The resource estimate of the St. Lawrence Fluorspar Project is approximately 30 years of production.

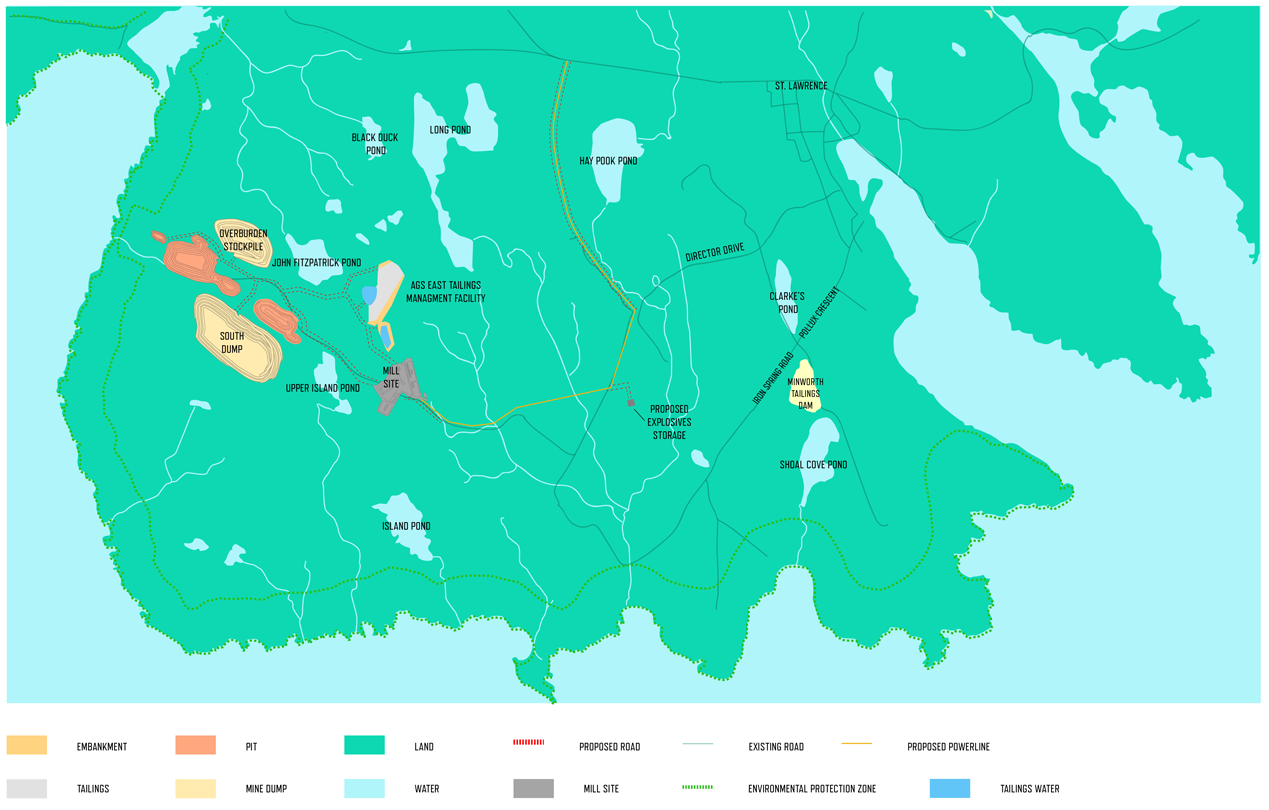

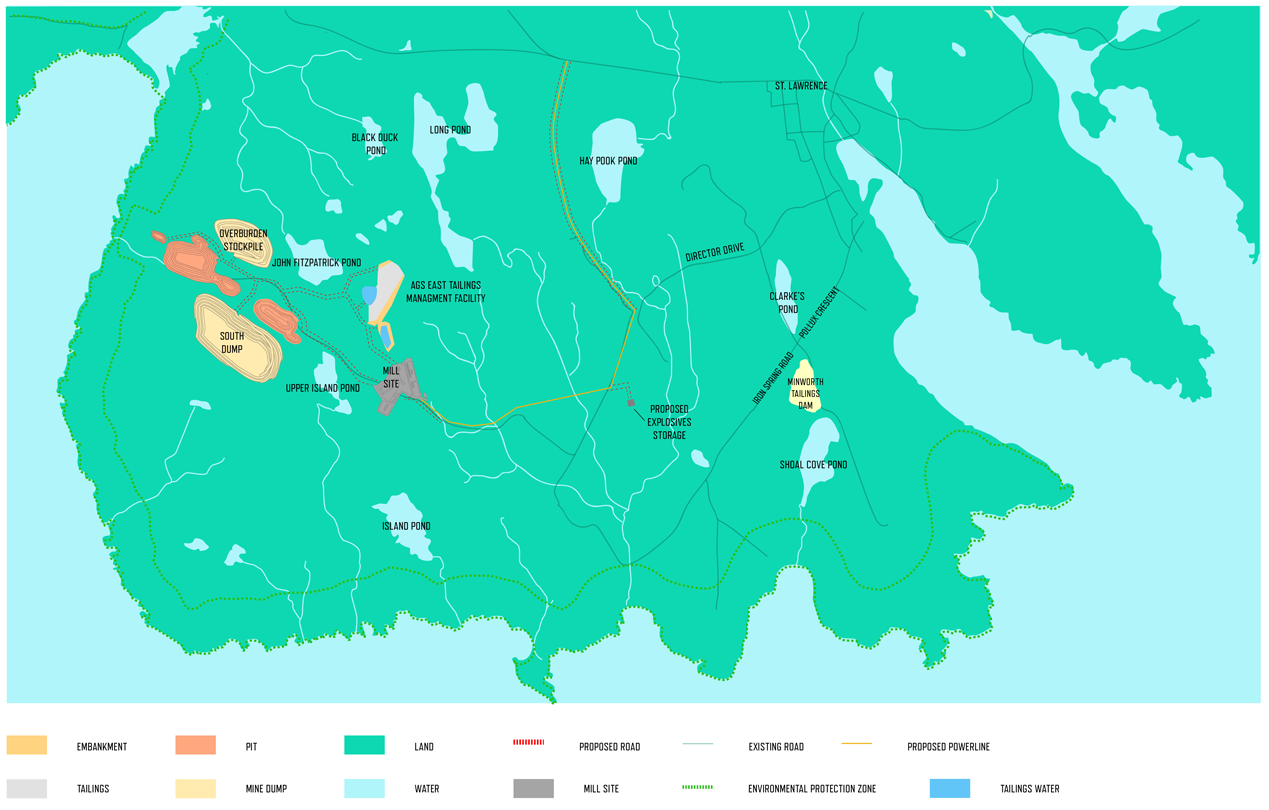

Open pit mining will occur in three pits: Grebes Nest Pit, Center Pit and Open Cut Pit. Grebes Nest Pit will be mined first with waste material from this pit used to construct mine roads and supply materials for the tailings dam construction. Grebes Nest Pit will be completed at the end of Year 2. Center Pit will be mined as Grebes Nest Pit is completed. The Open Cut Pit will be mined in Year 6, the last year of mining of the open pits.

The first year of mining will focus on ramp-up and commissioning the mill. Production will then increase to an average annual production of 200,000 tonnes of acid-grade concentrate.

Canada’s online casino is investing in mining companies because of the potential of the mine. This project is estimated to be St. The Lawrence Fluorspar Project is approximately 30 years old and contains over 900 million tons of ore and 157 million tons of heap leach reserves.

best payout casino Canada – fastpayout-casino.com/best-payout-online-casinos/ is a strategic investor in the mining project and will have certain rights under the deal. The casino has already invested in other mining companies, which increases their profits.

Overall General Arrangement

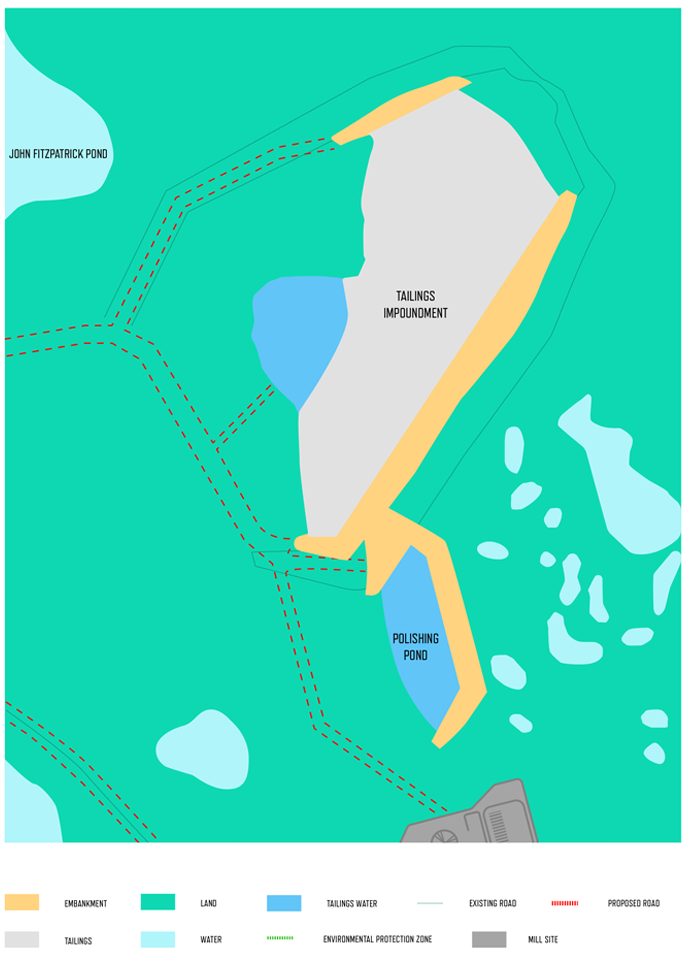

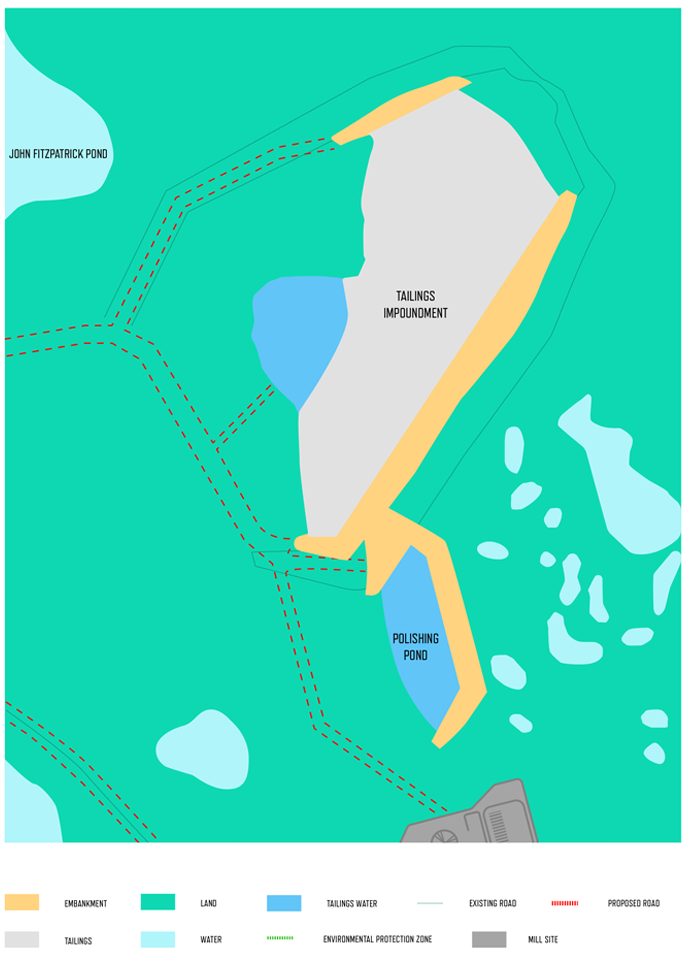

TAILINGS MANAGEMENT FACILITY

Tailings are produced as a byproduct of milling, and exist essentially as sand depleted of valuable mineral. The objective of tailings management is to confine the mill tailings and provide safe, long-term, low maintenance disposal. Tailings are stored in engineered structures called tailings impoundment areas, which can be created through the use of dams, berms, and natural features of the site such as hillsides.

It is common practice for tailings to be permanently stored in a secure facility at the site. For the St. Lawrence Fluorspar Project the 2.8 million tonnes of tailings will be stored in an area called AGS East. It will be located near the St. Lawrence Fluorspar mine site in a purpose-built tailings storage area.

slot depo 25slot777slot maxwinslot gacor 777slot gacorslot danaslot

PICTURES

Work continues at the St. Lawrence Fluorspar Project Site

A Drill in Operation

Work at the mine site

A Haul Truck waits for a rock load to remove from site.

The concrete base for the crushed ore stockpile tunnel

Cyclones in the mill building

Work on Flotation Cells is complete

A high pressure pump for the flotation cells

Progress continues on Town Bypass Road. The road will allow CFI to connect to highway systems without having trucks travel on municipal roads.

An overhead view of flotation cell banks.

Cyclones ensure particles of the right size get sent to flotation cell banks.

A reagent tank.

Doors are erected for the Mine Workshop. An inflatable structure will be attached to the doors for the main building portion.

The Ball Mill has been installed.

Power line work continues for the St. Lawrence Fluorspar Project site.

An aerial view of site – March 14, 2017.

Wheel Loader, Compactor ad Crawler Dozer

More equipment arrives on site

The mill building for the St. Lawrence Fluorspar Project